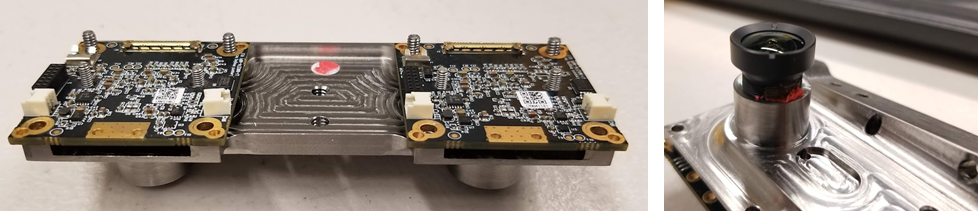

Invariant relative positioning and focus of cameras is vital for the success of MoonRanger’s stereo perception. The slightest change during mission can create inaccurate depth models and therefore non-functional obstacle avoidance. Positioning variables include the spacing between the cameras, their vergence (zero vergence in the case of MoonRanger), and their relative dip angle (“twist”). Camera focus is established by orientation and proximity of the lens to the focal plane array (set by threading the lenses inward or outward in the case of MoonRanger). This multi-functional positioning is achieved by MoonRanger’s highly-engineered camera mount.

Beyond setting these positioning variables perfectly before leaving Earth, it matters that these parameters remain invariant through the rover’s mission on the Moon. That is achieved by machining the mount from titanium. MoonRanger converged on this design after considering composite, aluminum and invar. Considerations include stiffness-to-weight ratio, changes in dimension due to thermal expansion and machineability. Aluminum and titanium were shortlisted, and titanium was chosen for the most important considerations of thermal stability and stiffness-to-weight ratio despite greater challenges of machining the titanium.

Camera Sensors & Lenses