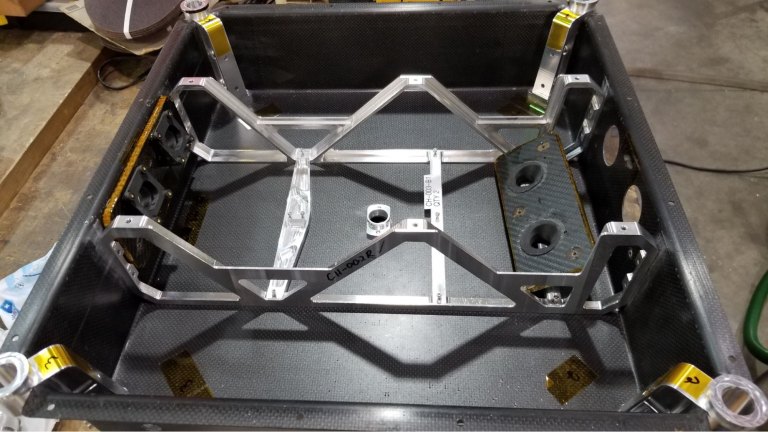

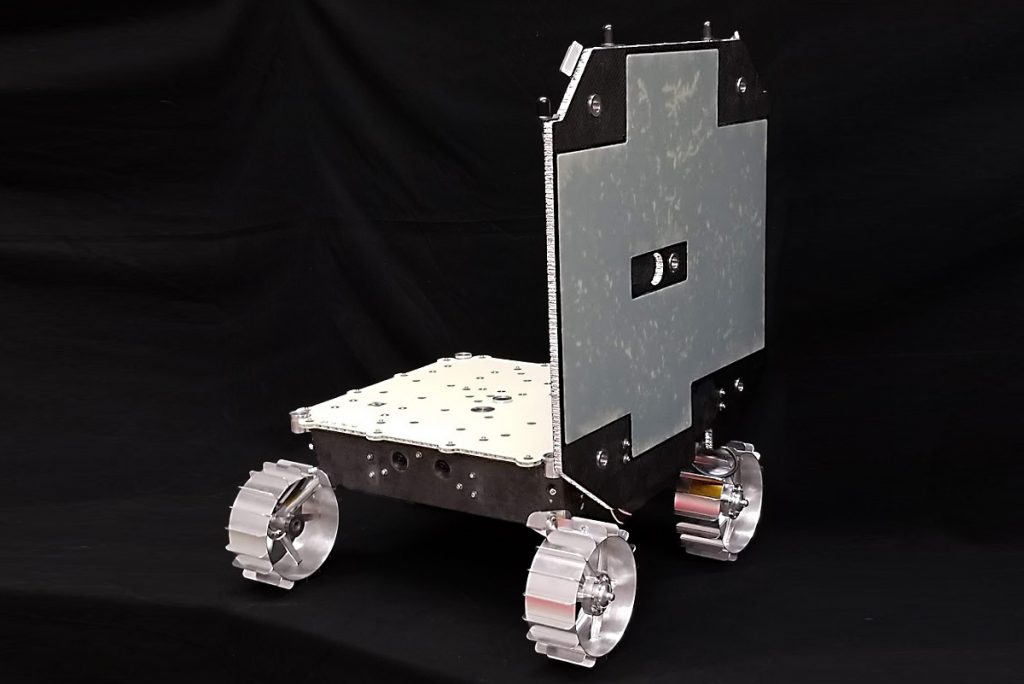

Fabrication methods (for example, of the composite chassis shell), as-demonstrated mobility, vibration test correlations to predictions, and other purposes require a high fidelity physical prototype whose tangible validity surpasses the design and analysis of early development. For these purposes Terramule was developed, served effectively, and continues to serve the MoonRanger program.

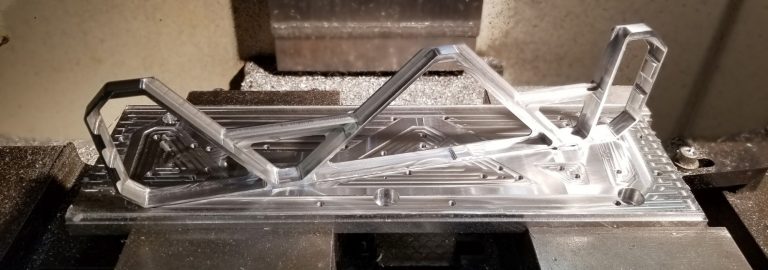

With material removal largely complete, the mold is thoroughly sanded and smoothed. MoonRanger’s chassis walls are drafted outwards at 5 degrees, which helps the chassis release from its mold once cured. The draft angle, smooth mold surfaces, and a mold release compound (Frekote) ensures release after the layup and curing process.

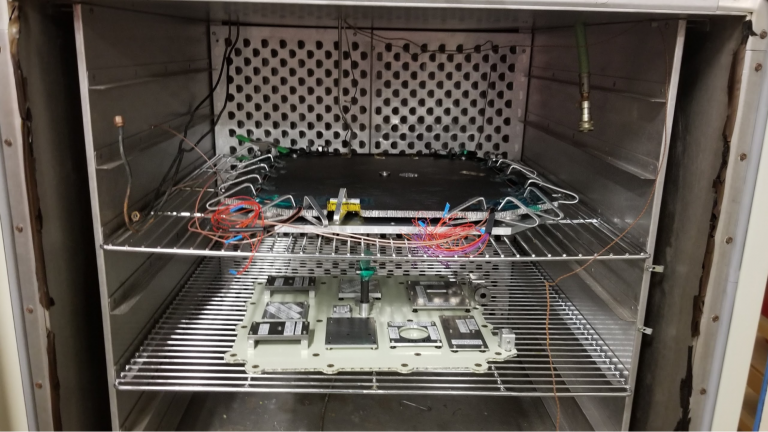

The chassis shell is laid up from 40 pieces of carbon fiber material in a lengthy, highly-disciplined process. It is then vacuum-bagged and cured in an autoclaved to eliminate voids and insure aerospace quality. Each step of the build process is carefully recorded, including such details as the humidity and temperature of the room during layup, the oven temperature and time spent under cure, and the vacuum used to press the prepreg layers against the mold. This record, along with complete traceability of the materials used in the build, comprise the certification ensuring the shell is built-as-designed. Shells removed from the mold must still undergo a series of machining operations to introduce mounting holes, pass-throughs, and cleanup excess material from the layup process.

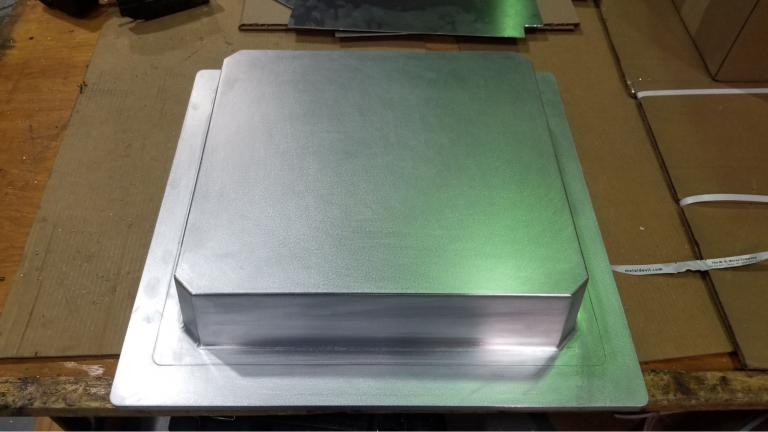

The solar panel (left) and radiator (right) both have aluminum honeycomb cores. The solar panel is skinned with carbon composite face sheets. The radiator is skinned with aluminum face sheets to maximize in-plane distribution of heat from the internal electronics and to maximize radiation of that heat to black space. The visible holes are eventually filled with potted inserts, which provide rigid threaded mounting points for structural components and for the rover’s avionics.