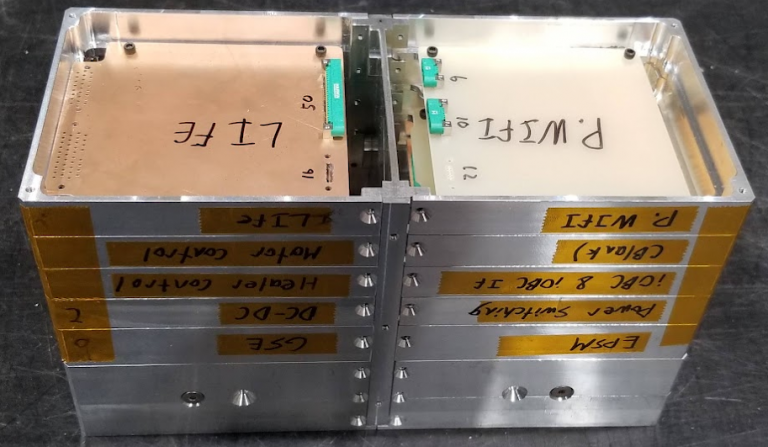

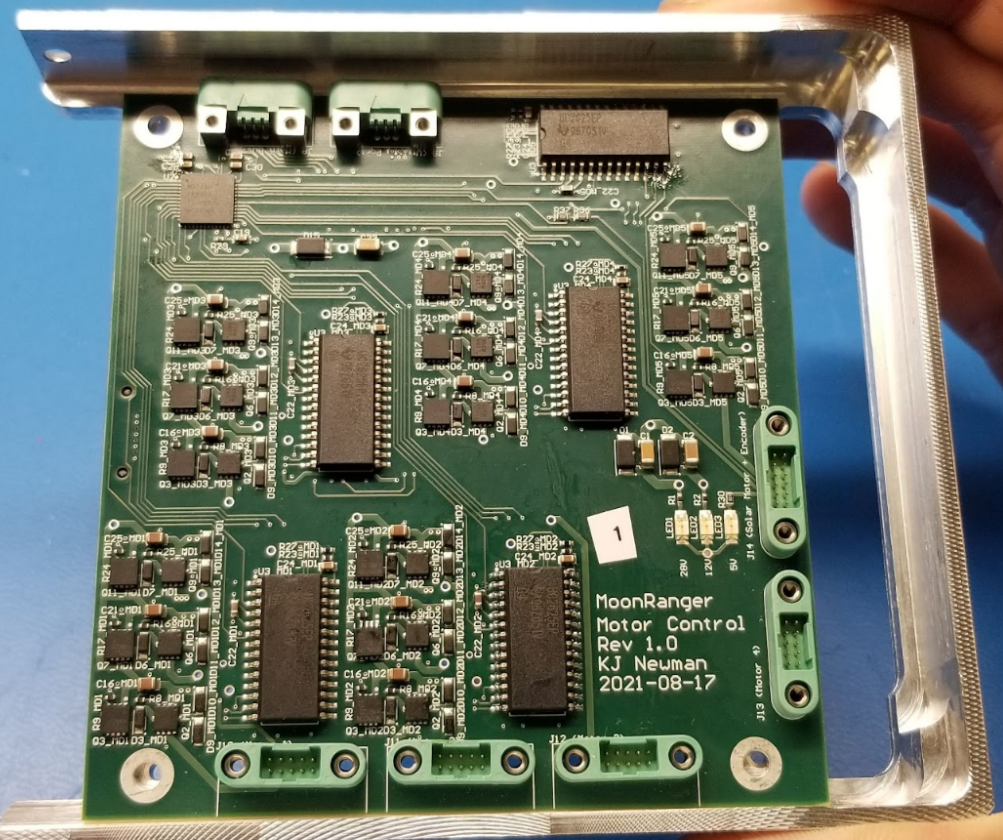

MoonRanger’s custom electronics take the form of a half dozen printed circuit boards that conform to CubeSatKit-standard dimensions. All these boards and mountings stack into the structural mounting system designated as a ‘LOAF’ in MoonRanger’s design. Read more about the mounting of electronic boards here.

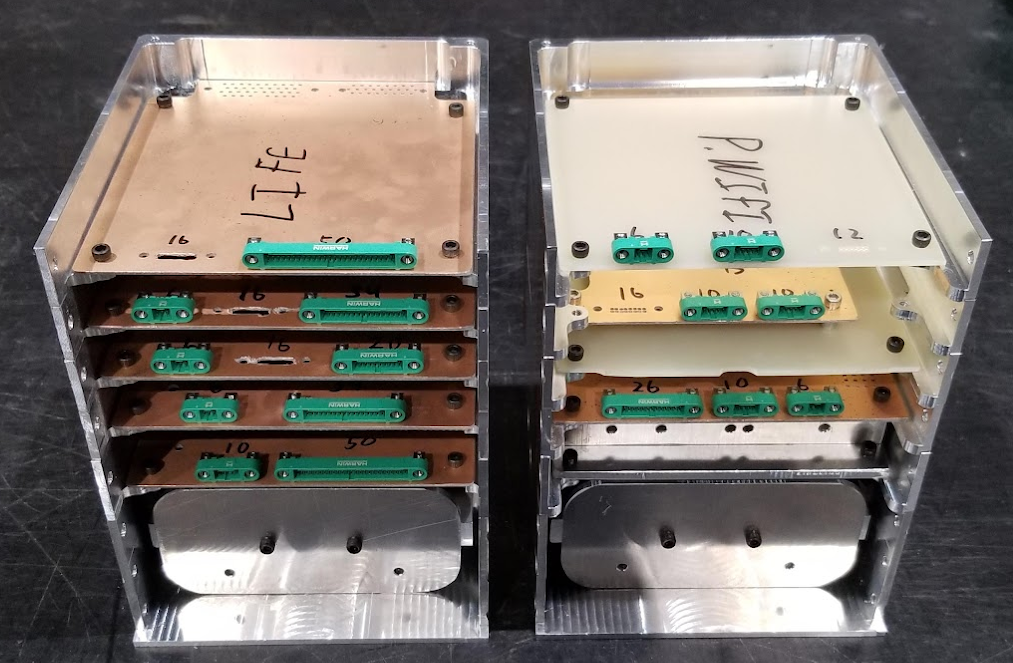

This assembly integrates pseudo-boards and pseudo-batteries with correct geometry and connectors, but without the functional electronics. Pseudo-boards match flight form factor and connector placement, but do not host any circuitry. Non-PCB avionics, such as the batteries, are represented by aluminum stand-ins.

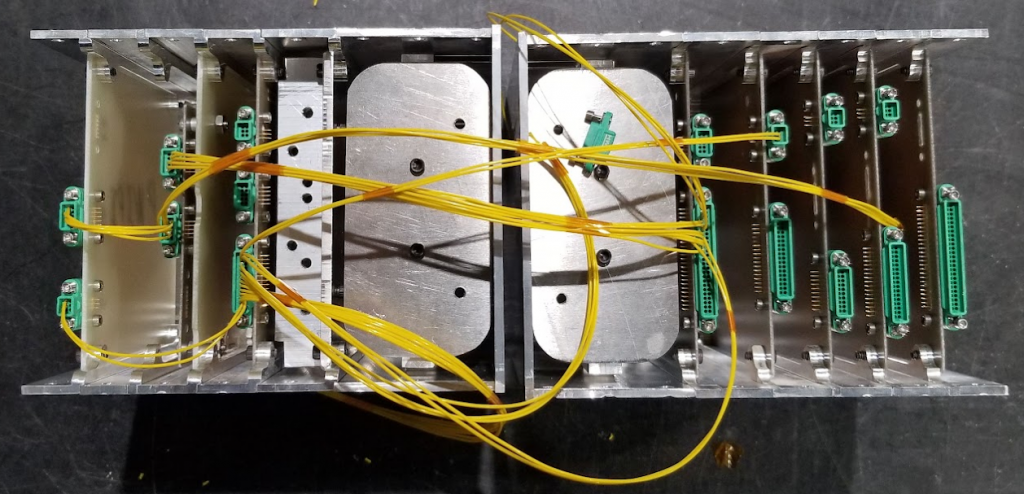

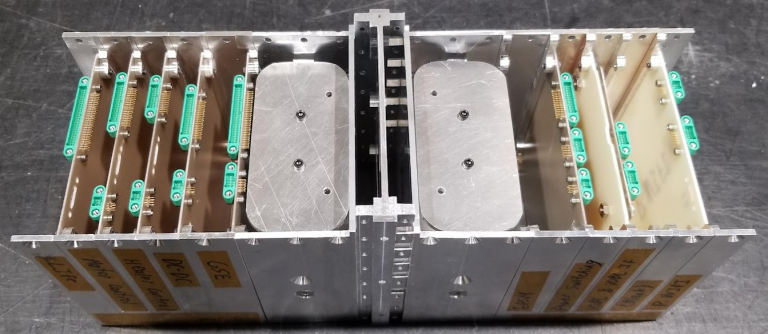

During integration, the avionics LOAF is split into halves to provide access for wire harnessing. The two LOAF halves close like a book, situating the wire raceways in the middle. An aluminum ‘spine’ helps isolate the EMI noise generated by boards on the left half from relatively noise-sensitive boards on the right. The spine also bolsters the structure and provides a mounting surface for heaters.

The primary purpose of the assembly is to mock up the board-to-board harnessing (wiring). This is distinct from the external harnessing that attaches the solar array, cameras, autonomy computer, motors and remote devices like the antennas and sun compass to these PCB boards. Successful harnessing (wiring) is a mix of art, tech and craft. It is most enabled by the mockup that this assembly enables.